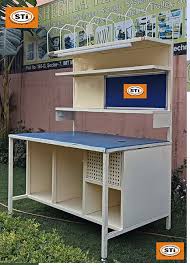

Packing tables are major stations in the packaging industry that can maximize efficiency in the warehouse, production unit, and e-commerce services. These tables enable the assembling, packing, and labeling of products before shipment. Most designs add shelving, drawers, and compartments to store useful toolsets and materials, from tape, scissors, and packing paper. Some models have height-adjustable conveyor rollers as ergonomic accessories that help reduce problems linked to operation while achieving smooth workflow. Such framework is built with materials that most often include stainless steel, wood, or heavy-duty plastic, ensuring prolonged durability, ideally weatherproof. A surprisingly high productivity boost through increased speed of packaging and better organization of the process has arisen from investments in a carefully designed packing station.

Benefits

Increased Efficiency: An improvement in the speed of packing operations with fewer delays and a better model of the flow in work.

Better Organization: The packing material from boxes to tape and other tools is stored for ease of access.

More Productive: Workers can work faster when their surroundings are orderly.

Reduced Strain on Workers: Ergonomically designed with an adjustable height to reduce stress and fatigue on the body.

Time Saving: Cut down on unnecessary steps, which accelerates packaging operations.